BMW Group expands e-drive production network: Start of battery component production in Leipzig and Regensburg

April 30, 2021 Press Release

BMW Group now producing high-voltage batteries

and battery components at three locations in Germany alone:

Dingolfing, Leipzig and Regensburg +++ Less than a year from

decision to start of production in Leipzig and Regensburg +++

Production of battery components for BMW Group’s fifth generation of

fully-electric vehicles

Munich/Leipzig/Regensburg. The BMW

Group is launching production of battery components at its plants in

Leipzig and Regensburg and expanding its e-drive production network.

It has been less than a year since the decision was made to expand

production capacity for e-drives in Germany. BMW Group Plant Leipzig

will launch series production of battery modules on Monday, 3 May

2021, while BMW Group Plant Regensburg began coating battery cells

for high-voltage batteries in April 2021. High-voltage batteries

will also be produced in Regensburg from 2022. “We expect at least

50 percent of the vehicles we deliver to our customers worldwide to

be fully electric by 2030,” said Michael Nikolaides, Senior Vice

President Production Engines and E-Drives. “And we are

systematically expanding our production network for electric drive

trains in response to this.”

The company is investing more than 250

million euros in its Regensburg and Leipzig locations alone to

supply the BMW Group’s growing number of electrified vehicles with

high-voltage batteries. High-voltage battery components will be used

in production of the BMW iX* and BMW i4, both of which will be

released onto the market shortly. The production systems are highly

flexible and will also supply battery components for other BMW Group

electrified vehicles in the future.

“We are increasing capacity at existing

locations and developing capabilities at others. In this way, we can

make the most of our associates’ expertise and experience and offer

them long-term, secure jobs,” Nikolaides added. The BMW Group is

investing a total of around 790 million euros in expanding

production capacity for drivetrain components for electrified

vehicles at its Dingolfing, Leipzig, Regensburg and Steyr locations

between 2020 and 2022.

Leipzig is the BMW Group’s pioneer plant

for electromobility and has been building the BMW Group’s first

fully-electric vehicle, the BMW i3*, since 2013. Now, the location

will also produce electric drivetrain components.

“We are continuing on this track with

the launch of battery module production and further enhancing the

plant’s future viability for electromobility,” confirmed Hans-Peter

Kemser, Plant Director of BMW Group Plant Leipzig. “Plant Leipzig

will play an important role in supplying the growing number of BMW

Group electrified vehicles with battery components.” The successor

to the MINI Countryman, scheduled to come off the production line in

Leipzig from 2023, will be released onto the market with an electric

drive train. “The expertise and experience gained by staff at our

location over the years can be put to good use. Construction of the

battery module lines will make a major contribution to long-term job

security,” emphasised Kemser.

From May 2021, the 10,000 sq. m.

production area previously reserved for the BMW i8 will be used for

manufacturing battery modules. Production will get underway with 80

employees working in battery module production; by the end of the

year, there will be a staff of around 150. The company will invest

more than 100 million euros in the initial phase of battery module

production at the Leipzig location between 2020 and 2022.

However, the production line for battery

modules that just ramped up is only the beginning: The company has

already decided to further increase capacity for battery module

production at its Leipzig location. A second production line will

come on stream in 2022. This will ensure the company has sufficient

volumes to meet growing demand for drivetrains.

BMW Group Plant Regensburg already

produces two electrified models – plug-in hybrid variants of the BMW

X1* and BMW X2* – and will start building the fully-electric BMW X1

in 2022. The site's e-mobility expertise and experience will now

also be used in production of battery components and high-voltage

batteries.

The first of four coating lines for

fifth-generation battery cells went on stream in April 2021,

occupying a production and logistics area of more than 40,000 sq. m.

“Regensburg has made a successful start to production of electric

drivetrain components – this is an important milestone in our

transformation,” according to Frank Bachmann, Plant Director of BMW

Group Plant Regensburg. The three other systems will ramp up in

stages between now and the end of 2021 to supply the growing volumes

needed for the BMW Group’s fully electric vehicles. Up until now,

battery cells have been coated at BMW Group Plant Dingolfing and the

BMW Brilliance Automotive Plant Powertrain in Shenyang, China.

Coating increases the battery cell’s

mechanical robustness and thermal conductivity. This helps improve

insulation and cooling of the fifth-generation e-drive’s even more

powerful battery cells. From 2022, the plant in Regensburg will

produce high-voltage batteries from battery modules. A total of 100

employees already work in battery component production at the

Regensburg site; by the end of 2022, there will be more than 300.

The company will invest more than 150 million euros in ramping up

production of battery components and high-voltage batteries between

2020 and 2022.

The BMW Group has a clear mission to

ensure the “greenest electric vehicle comes from the BMW Group”,

starting in production. The BMW Group already sources only green

power for its manufacturing locations worldwide.

The BMW Group’s energy goals are geared

towards the long term. The company reduced its emissions per vehicle

produced by more than 70 percent between 2019 and 2006.The aim is to

lower these CO2 emissions by another 80 percent by 2030. This means

the BMW Group will have reduced its CO2 emissions from production to

less than ten percent of what they were in 2006.

A further corporate objective is to

reduce CO2 emissions in the supplier network by 20 percent by 2030.

At the same time, the BMW Group has reached an agreement with its

suppliers that they will only use renewable green power for

producing fifth-generation battery cells.

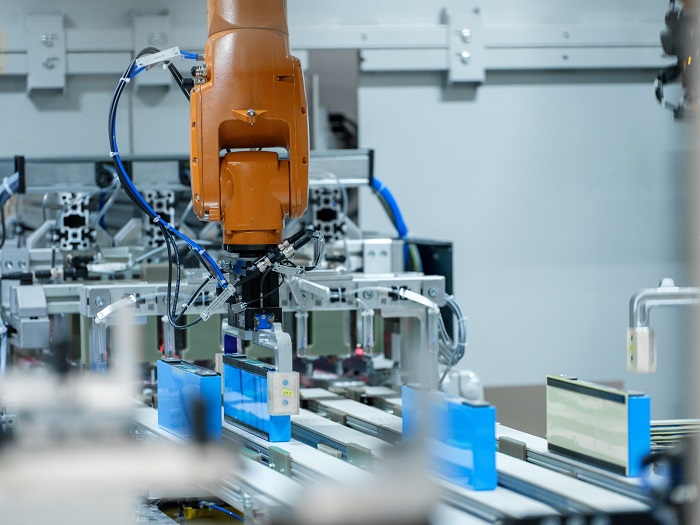

Production of high-voltage batteries can

be broken down into two stages: Battery modules are produced in a

highly automated process. The lithium-ion cells first undergo a

plasma cleaning, before a specially developed system coats the cells

to ensure optimal insulation. Next, the battery cells are assembled

into a larger unit, the so-called battery module. The BMW Group

obtains its battery cells from partners who produce them to the

company’s exact specifications. The BMW Group uses different battery

cells, depending on which provides the best properties for each

vehicle concept.

The battery modules are then installed

in an aluminium housing, together with the connections to the

vehicle, and the control and cooling units. The size and shape of

the aluminium housing and the number of battery modules used differ

according to the vehicle variant. This ensures the high-voltage

battery is optimally adjusted to the vehicle.

The high-voltage batteries and battery

components needed for all BMW and MINI electrified vehicles come

from the company’s own battery factories in Dingolfing, Leipzig and

Regensburg in Germany, as well as from Spartanburg (USA) and

Shenyang (China). The BMW Group has also localised production of

high-voltage batteries in Thailand, at its Rayong plant, and is

working with the Dräxlmaier Group for this. Munich is home to the

e-drive pilot plant and the Battery Cell Competence Centre, where

the BMW Group is conducting a full analysis of battery cell value

creation processes and refining technology for its production

processes.

The company produces electric motors at

the Competence Centre for E-Drive Production in Dingolfing and at

BMW Group Plant Landshut. BMW Group Plant Steyr builds the housing

for the highly integrated fifth-generation e-drive.

With the BMW Group’s electro-offensive

now in full swing, increased production capacity is needed for

electric drivetrain components. Thanks to intelligent vehicle

architectures and a highly flexible production network, the BMW

Group will have about a dozen fully-electric models on the roads

from 2023. The BMW i3*, MINI Cooper SE* and BMW iX3* already on the

market will be joined later this year by the BMW iX* and BMW i4.

Between now and 2025, the BMW Group will increase its sales of

fully-electric models by an average of well over 50 percent per year

– more than ten times the number of units sold in 2020. By the end

of 2025, the company will have delivered a total of around two

million fully-electric vehicles to customers. Based on current

market forecasts, the BMW Group expects at least 50 percent of its

global sales to come from fully-electric vehicles in 2030. In total,

over the next ten years or so, the company will release about ten

million fully-electric vehicles onto the roads.

This means the BMW Group is

strategically on track to reach the European Union’s ambitious CO2

reduction targets for 2025 and 2030 as well.

CO2 EMISSIONS & CONSUMPTION.

BMW i3: Fuel consumption combined:

0.0 l/100 km; power consumption combined: 16.3-15.3 kWh/100 km WLTP;

CO2 emissions combined: 0 g/km.

BMW i3s: Fuel consumption combined:

0.0 l/100 km; power consumption combined: 16.6-16.3 kWh/100 km WLTP;

CO2 emissions combined: 0 g/km.

MINI Cooper SE: Fuel

consumption combined: 0.0 l/100 km; power consumption combined:

17.6-15.2 kWh/100 km WLTP, CO2 emissions combined: 0 g/km

BMW iX3: Fuel

consumption combined: 0.0 l/100 km; power consumption combined:

17.8-17.5 kWh/100 km WLTP, CO2 emissions combined:

0 g/km.

BMW iX xDrive50: Power

consumption combined: < 21 kWh/100 km in the WLTP test cycle; CO2 emissions

combined: 0 g/km (data is provisional and based on forecasts)

BMW iX xDrive40: Power

consumption combined: < 20 kWh/100 km in the WLTP test cycle; CO2 emissions

combined: 0 g/km (data is provisional and based on forecasts)

BMW X1 xDrive25e: Fuel

consumption combined: 1.9-1.7 l/100 km WLTP, power consumption

combined: 15.4-15.0 kWh/100 km WLTP; CO2 emissions

combined: 43 g/km.

BMW X2 xDrive25e: Fuel

consumption combined: 1.9 l/100 km WLTP; power consumption combined:

13.7 kWh/100 km WLTP, CO2 emissions combined: 43 g/km. |