BMW iX3 Electric Sports Activity Vehicle

BMW iX3 Electric Sports Activity Vehicle

|

|

|

|

Munich. The BMW iX3, the production of which will commence in

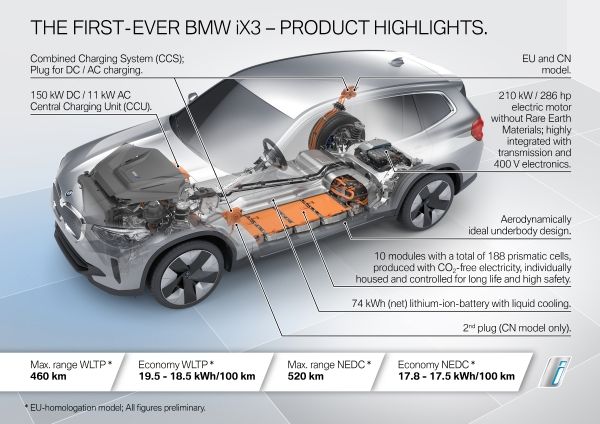

late 2020 in China, facilitates locally emission-free driving in a novel and efficient form, whilst also being suitable for everyday use. A range of more than 440 km* within the legislative WLTP test cycle will be achieved with a net-battery size of 74 kWh*. The first purely electric Sports Activity Vehicle (SAV) is the trailblazer for BMW eDrive technology of the fifth generation, which, starting 2021, will also be deployed in the BMW i4 and the BMW iNEXT. For this purpose, both the drive system and the high-voltage battery unit featuring pioneering battery cell technology have been completely redeveloped. In the BMW iX3, the related advancement ensures brand-typical driving experience combined with outstanding efficiency and a novel balance of weight and range. The BMW iX3 is yet a further milestone in the consistent realization of the BMW Group’s electrification strategy. In 2020 the BMW X3 will become the brand’s first model available both with conventional petrol and diesel engines as well as plug-in hybrid and purely electric drive. With this “power of choice” offer, the globally operating company is taking into account the various different requirements and needs of their worldwide customers worldwide as well as maximum effectiveness in the reduction of CO2 emissions. The BMW iX3 is produced for the world market by the joint venture BMW Brilliance Automotive in Shenyang, China. The fifth-generation BMW eDrive technology is the key to future-oriented sustainability for vehicles with electrified drive systems. It is the result of consistent development work within the framework of BMW EfficientDynamics and the experience gained by the BMW Group in the field of electric mobility spanning more than 10 years. All powertrain components used for BMW eDrive technology were developed solely by the BMW Group. Moreover, the electric motor and the high-voltage batteries are produced in corporately owned manufacturing facilities. In this way, the BMW Group ensures it has a decisive influence on the product properties and the quality of each component. Furthermore, the drive unit and the high-voltage battery unit are flexibly scalable in terms of power and energy content and can thus be used in various different vehicle concepts and segments. EfficientDynamics at its best: New drive component with high efficiency and brand-typical power characteristics. In the BMW iX3, EfficientDynamics reaches a new level. The vehicle’s fifth-generation BMW eDrive technology comprises a drive unit in which electric motor, system electronics and transmission are brought together into a central housing. As a result, the required installation space of the drive technology and its weight are considerably reduced. The ratio between motor output and weight of the drive system improves around 30 percent compared to the previous generation. The electric motor featured in the BMW iX3 delivers a maximum power output of 210 kW/286 hp*. The torque of 400 Nm* allows for high initial acceleration and keeps a high level even at the upper motor speeds because of exclusive BMW design measures. A further special feature of the electric motor being deployed in the BMW iX3 for the first time is a construction method that eliminates the need for rare earth materials. The electric motor used in the BMW iX3 transfers power to the rear wheels. This effectuates a further increase in drive system efficiency. Moreover, the range of the BMW iX3 benefits from the drive design conveying the traditional BMW rear-wheel drive experience.

High-voltage batteries with significant higher energy density and responsible use of raw materials. The high-voltage battery unit of the BMW iX3 is integral part of BMW’s fifth eDrive generation and is based on the latest evolution in NMC-811 technology in BMW typical prismatic design. The BMW Group has outstanding development capabilities in this field. This know-how flows into precise specifications with regard to the use of materials and battery design, according to which the battery cells are produced. Consistent research and development work not only raises energy density but also constantly improves all battery cell characteristics, in particular also durability and safety. In total, the BMW high-voltage battery shows the optimum of what is possible nowadays. At the same time the BMW engineers were able to reduce the share of cobalt contained in the battery by another two thirds. Compared to former technology used by BMW Group, the gravimetric energy density on cell level in the BMW iX3 is around 20 percent higher. With the BMW iX3 the raw materials Cobalt and Lithium for the first time are purchased by BMW directly and then handed over to the producer of the battery cells. In addition, scalability and the compact design of the high-voltage battery unit have been further optimised. The battery cells are grouped into modules at specialized BMW production locations and finally assembled as high-voltage battery packs aligned to each model. The high-voltage battery unit in the BMW iX3 is installed in an extremely flat position in the vehicle floor. Thanks to this arrangement, there is no loss of space for passengers and the luggage compartment compared to the conventionally powered versions of the BMW X3. Greater range thanks to high efficiency rather than a bigger battery With a net energy content of 74 kWh*, the high-voltage battery unit installed in the BMW iX3 achieves a range of more than 440 km* in the legislative WLTP test cycle. Within its segment, the BMW iX3 boasts not only a unique low power consumption of less than 20 kWh/100km* accordingly to the WLTP test cycle, but also stands for a novel ratio between battery size and range. Thanks to the favourable efficiency rating of the drive components and the high energy density of the high-voltage battery unit, the BMW iX3 achieves a range that is only possible for common electric vehicles with larger and thus heavier batteries. Positive environmental impact secured. The “real” ecological footprint of electric vehicles is sometimes questioned, particularly in markets still having a low percentage of green electricity in the public power grid. At the BMW Group every electrified model has to proof that for the entire cycle, comprising raw material procurement, supply chain, production and usage phase as well as recycling, its CO2 balance is substantially better than the one of a conventionally powered sibling. For the BMW iX3 the related advantage is more than 30 percent compared to a BMW X3 sDrive 20d when average European power supply is used during the car’s usage phase. If the vehicle is charged with green electricity the advantage is around 60 percent. Furthermore, in analogy with the BMW i3 Plug&Play technology, the high-voltage battery featured in the BMW iX3 is planned for a second life as a stationary battery pack for the period following the first long life in the car. This way the already positive CO2 balance of the BMW iX3 can be further improved. * = preliminary data |

|

Start of

production for fully-electric BMW iX3 10/02/2020 Press Release First BMW iX3 comes off production line at

BMW Brilliance Automotive in Shenyang, China

Munich/Shenyang. The

first fully-electric BMW iX3 has left the production line at the BMW

Brilliance Automotive joint venture (BBA) in Shenyang, China. The

workforce at the BBA Plant Dadong in Shenyang already celebrated the

successful start of production on 29 September 2020.

Franz Decker, head of BBA's Technology and Production division, said

during the event: “Today, we begin production of the BMW iX3, the

first pure electric model from our core BMW brand. With a production

system like this, specialised for high quality, we are able to

deliver what customers worldwide demand from premium vehicles.”

Leading production expertise guarantees premium quality

As well as intelligent manufacturing and state-of-the-art

technologies, the BBA production facility in Shenyang is also

distinguished by its comprehensive quality management system. A

special "zero defect concept" ensures that the globally high market

requirements for electric mobility are met.

BBA conducts rigorous testing of everything from the battery to the

finished car to guarantee the vehicle safety of the BMW iX3. 128

mechanical tests and 994 software functionality tests ensure the

high quality of high-voltage batteries throughout the entire

lifecycle. 140 functional tests check every aspect of the vehicle

during acceleration, in particular road conditions and on rocky

roads. As a result, the BMW iX3 is well-suited for all types of

roads and meets the high demands of different driving conditions.

BBA produces the fully-electric BMW iX3 on the same line as the BMW

X3 with combustion engine to ensure a high level of efficiency and

flexibility in production.

During the entire BMW iX3 project, the BMW Group's research and

production, purchasing and production divisions worked closely with

BBA.

CO2 EMISSIONS & CONSUMPTION.

BMW iX3: Fuel

consumption combined: 0.0 l/100 km; power consumption combined:

17.8-17.5 kWh/100 km; CO2 emissions combined: 0 g/km. |